Pneumatic Drill Units

The air motor characteristics of Airmachines’ Self Feed Units give optimum life to the drill bit and produce an optimum quality hole. As the bit dulls, the motor slows and torque increases, extending cutting ability. This motor characteristic and the variable thrust of the air cylinder balance both the torque and thrust. The result is optimum cycle time for a given material and drill bit, limited only by the maximum capacity of the unit.

TOOL FEATURES / ENGINEERING MANUAL| Model No. | Free rpm | Std. Chuck Size | Gear Reductions | Length | Weight |

|---|---|---|---|---|---|

| DD5A06C | 600 | 3/8" (10 mm) | Double | 23 3/4" (603 mm) | 9.8 lbs (5.1 kg) |

| DD5A09C | 900 | 3/8" (10 mm) | Double | 23 3/4" (603 mm) | 9.8 lbs (5.1 kg) |

| DD5A15C | 1500 | 3/8" (10 mm) | Double | 23 3/4" (603 mm) | 9.8 lbs (5.1 kg) |

| DD5A25C | 2500 | 3/8" (10 mm) | Single | 22 7/32" (572 mm) | 9.3 lbs (4.9 kg) |

| DD5A33C | 3300 | 3/8" (10 mm) | Single | 22 7/32" (572 mm) | 9.3 lbs (4.9 kg) |

| DD5A50C | 5000 | 3/8" (10 mm) | Single | 22 7/32" (572 mm) | 9.3 lbs (4.9 kg) |

| DD5A170C | 17000 | 1/4" (6.5 mm) | Single | 22 7/32" (572 mm) | 9.3 lbs (4.9 kg) |

- 1/2 HP pneumatic motor.

- Hardened steel gearing with full bearing support.

- Pneumatic feed cylinder.

- Built-in exhaust throttles for feed cylinder piston speed.

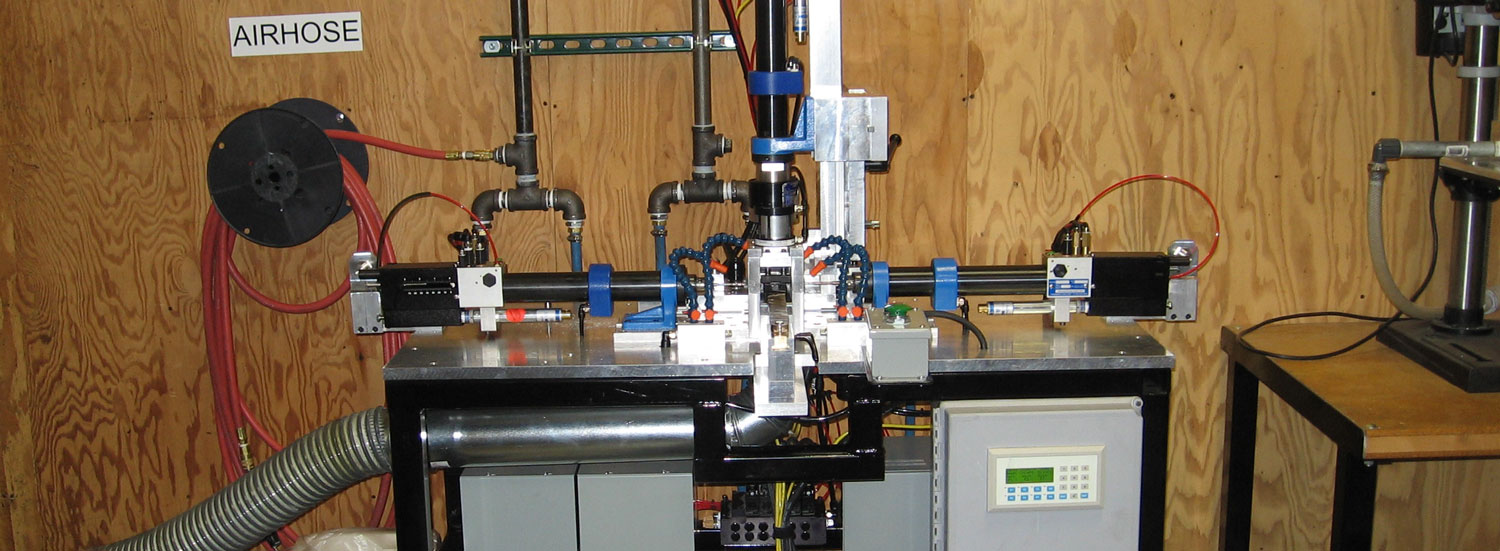

- Built-in controls for either manual, semi-automated, or fully automated machine controls

The standard multi-function Control Head for both the Electric and Pneumatic Drill Units includes built-in control valving, feed rate speed controls, return dwell ports, remote start and emergency retract ports. No need to purchase a separate external control valve package. Ready to drill holes right out of the box.

Each basic unit is supplied with a standard 3/8″ – 24 UNF threaded output spindle with a standard 3/8” capacity keyed drill chuck. The unit is setup to utilize dual air supply ports for powering the air motor and feed cylinder independently for greatest performance. Alternately, the units can be quickly changed to a combined air supply port which means the feed cylinder only utilizes the backpressure of the air motor.

Optional attachments include tapping heads and multi-spindle drilling heads with a wide range of collet sizes.

Pneumatic Tapping Units

The ability to vary torque and feed rate independently on Airmachines’ Self Feed Units provides the unit with a unique characteristic. It can function as a lead screw tapper, using the tap itself as the lead screw.

Two types of tapper heads are available. The heavy-duty head on the 600 and 900 rpm units is capable of tapping up to 3/8″ threads. The medium duty head on the 1500 rpm unit is capable of tapping up to 1/4″ threads. Positive drive chucks are available with flex collets, see Flex Collet chart at the right.

Range Of Flex Collets For Tapping Unit Chucks

600 and 800 rpm

| Collet Range | Part No. |

| 1/8”-1/4" | PT7995/570 |

| 1/4”-3/8" | PT7995/570A |

1500 rpm

| Collet Range | Part No. |

| 0.176-0.256 | J117 |

| 0.146-0.198 | J113 |

Tapping Unit Technical Data

| Model No. | Free rpm | Std. Collet Size | Length | Weight |

|---|---|---|---|---|

| TD5A06D | 600 | 5/16" Tap (9 mm) | 26 9/16" (699 mm) | 11.2 lbs (5.09 kg) |

| TD5A09D | 900 | 5/16" Tap (9 mm) | 26 9/16" (699 mm) | 11.2 lbs (5.09 kg) |

| TD5A15D | 1500 | 1/4" Tap (6.5 mm) | 25 9/16" (674 mm) | 12.3 lbs (5.58 kg) |