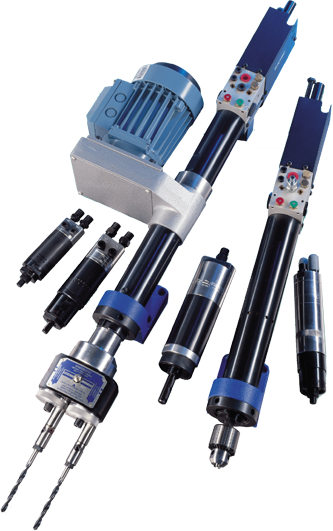

Manufacturers of Air Motors, Self-Feed Drill Units, and Air Feed Drills

Welcome to the home of Airmachines.com, Inc. We manufacture quality Pneumatic and Electric Self–Feed Drill Units and Air Motors for production drilling and tapping applications.

Airmachines Fixtured Air Drills

INCREASE productivity by eliminating manual operations and by combining two or more steps into one.

IMPROVE accuracy and product quality.

REDUCE scrap and prolong tool life through the precise control of the production process.

The versatility of the Airmachines fixtured air tools and air feed drills provide both large and small Manufacturing plants with a practical solution for drilling and tapping applications. After large runs of a popular product, they can easily be adapted for shorter runs of another product or set up for a completely different manufacturing process. Along with the simplicity of pneumatic controls, semi or fully automated fixtures and machinery can greatly reduce your manufacturing costs.

Why Airmachines over our competitors?

- Two week average shipping time. Expedited orders available in most cases.

- Multi-function Control Head set-up for either manual, semi-automated, or fully automated machine control.

- Self-Feed Drill Units come standard with built-in control valving, feed rate controls, return dwell ports, remote start and emergency retract ports.

- No need to purchase a separate external valve package. Ready to drill holes right out of the box.

- Variety of mounting brackets are available to provide versatility for machine designers.

- Application assistance and after sale service.

What Is an Air Feed Drill?

Air feed drills are precision-driven tools designed to automate the drilling process by using compressed air to advance the drill bit into the material. Unlike manual drilling methods, these drills apply consistent feed pressure, resulting in cleaner holes, reduced operator fatigue, and increased production efficiency. At Airmachines.com, Inc, we specialize in manufacturing durable and high-performing air feeding drills tailored for a variety of industrial applications, from light manufacturing to heavy-duty production lines.

By harnessing the power of pneumatics, air feeding drills ensure accurate hole placement and consistent results, regardless of the material being drilled. They can be used in semi-automated or fully automated setups, making them ideal for companies looking to improve throughput and maintain high-quality standards. This versatility has made them a preferred choice in industries such as automotive, aerospace, electronics, and general manufacturing. In addition, their ability to integrate seamlessly with existing production equipment makes them a cost-effective upgrade for facilities seeking to modernize operations. With minimal maintenance requirements and long-lasting performance, air feeding drills provide exceptional value while helping manufacturers meet tight production deadlines.

Precision Drilling With Air Feed Technology

Precision is at the core of what air feeding drills offer. Every project demands accuracy, and even small deviations can result in costly rework or rejected parts. Airmachines.com, Inc designs air feeding drills with built-in control valving and adjustable feed rates, ensuring that every hole is drilled to exact specifications. Our engineering team understands the challenges manufacturers face, and we provide solutions that minimize variability and maximize productivity.

Our air feed drills excel in maintaining uniform feed pressure and depth control, allowing for consistent hole sizes even during high-volume production runs. This precision not only improves product quality but also extends tool life, reducing the need for frequent bit replacements. Whether you’re drilling into metals, plastics, composites, or wood, our technology is engineered to deliver reliable results.

For businesses seeking to enhance repeatability, integrating air feeding drills into the production line offers a proven way to improve both quality control and output speed. These tools can also be customized to fit specialized applications, giving manufacturers greater flexibility in meeting diverse production requirements. With robust construction, easy maintenance, and dependable performance, our air feeding drills are built to keep operations running efficiently day after day.

How Air Feed Drills Improve Productivity

In fast-paced manufacturing environments, time is a critical resource. Air feeding drills from Airmachines.com, Inc help streamline operations by eliminating unnecessary manual effort and reducing cycle times. Because they deliver consistent feed pressure automatically, operators can focus on quality monitoring and other value-added tasks rather than manually applying force to the drill.

The automation provided by air feeding drills means less operator fatigue and fewer errors caused by inconsistent manual pressure. This directly translates to improved throughput, higher yield rates, and reduced scrap. When paired with our advanced pneumatic controls, these drills can operate continuously with minimal downtime, further optimizing production schedules.

From small shops to large-scale factories, the productivity gains from implementing air feeding drills are significant. Faster drilling cycles combined with consistent accuracy help businesses meet tight deadlines and keep pace with growing demand without compromising on quality. Additionally, the reduced strain on operators can contribute to a safer work environment and lower turnover rates. By improving efficiency and reducing waste, air feeding drills not only enhance production capabilities but also help manufacturers achieve a better return on investment over time.

Key Features of Our Air Feed Drills

At Airmachines.com, Inc, our air feeding drills are designed with features that address the real needs of modern manufacturers. Each unit comes standard with built-in control valving, feed rate adjustments, and return dwell ports, eliminating the need for expensive external valve packages. This ready-to-use configuration means you can start drilling right out of the box.

Other notable features include remote start and emergency retract ports for improved operator control and safety. Our drills are also compatible with a variety of mounting brackets, offering flexibility for machine designers to integrate them into existing production setups. The robust construction ensures that our air feeding drills can withstand continuous use in demanding environments while delivering long-lasting performance.

Additionally, we offer a multi-function control head that supports manual, semi-automated, or fully automated operation. This adaptability allows our air feeding drills to fit seamlessly into diverse production lines, regardless of the level of automation. Combined with our commitment to quality manufacturing and responsive customer support, these features make our drills a dependable choice for businesses seeking efficiency, safety, and precision in their operations.

Applications for Air Feeding Drills in Manufacturing

The versatility of air feeding drills makes them an invaluable asset across multiple manufacturing sectors. In the automotive industry, they are used for producing precision-drilled components that must meet strict safety and performance standards. Aerospace manufacturers rely on them for drilling into lightweight composites and high-strength alloys, where precision is non-negotiable.

In electronics manufacturing, air feed drills are ideal for creating clean, accurate holes in delicate circuit boards and enclosures. Furniture and cabinetry shops use them for repetitive drilling tasks in wood and engineered materials, improving consistency while reducing labor costs. They are also used extensively in metal fabrication shops, where speed and accuracy can make the difference between profit and loss on a project.

Regardless of the application, Airmachines.com, Inc provides the engineering support and product quality that manufacturers need to get the most out of their investment in air feeding drills. Our team works closely with clients to recommend the right configuration for each unique production environment, ensuring optimal performance and reliability.

When it comes to enhancing drilling operations, air feeding drills from Airmachines.com, Inc deliver the precision, speed, and durability that modern manufacturers require. Contact us today to learn more about integrating these advanced tools into your production process and experience firsthand how they can elevate your manufacturing efficiency.